The Pulverised Coal Injection Plant was added to the Cockerill-Sambre steel works in Charleroi in the early 1990s. The site became Carsid and was closed in 2008.

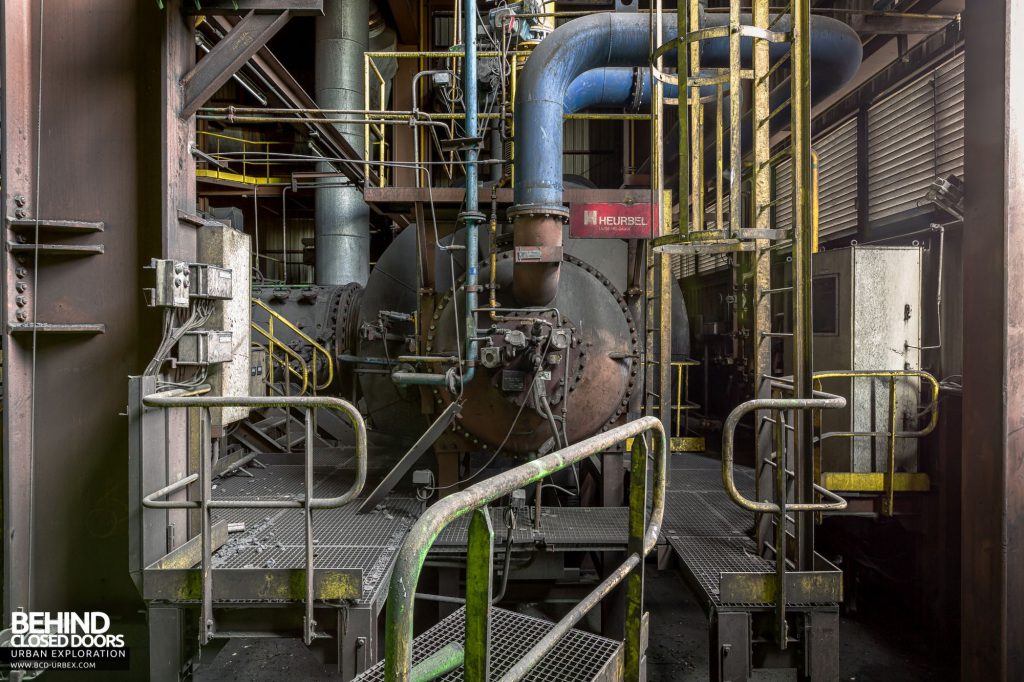

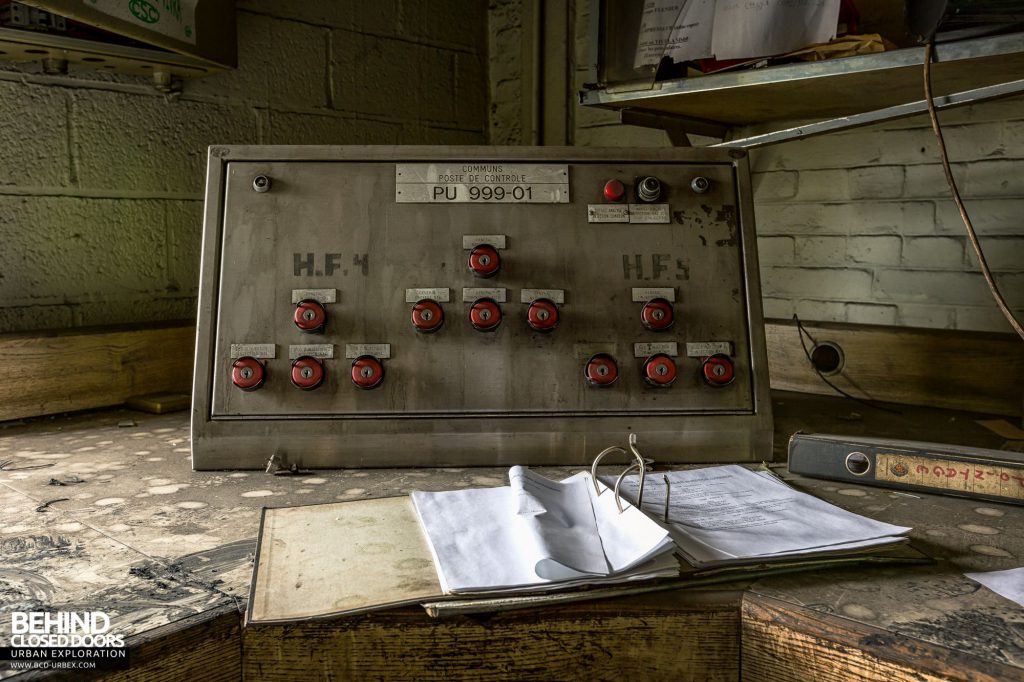

The Injection Charbon, or Pulverised Coal Injection (PCI) Plant at the HF4 Blast Furnace was a later addition to the Cockerill-Sambre site, built around 1991.

The traditional way of releasing molten iron from iron ore in a blast furnace is to burn coke in the blast furnace along with iron ore, while blasting hot air in to aid combustion. The blast furnace technique of iron production is constantly evolving and new technologies are often implemented. One such technology, Pulverised Coal Injection started to be implemented in the 1970s. Pulverised coal is mixed into the primary air supply and blown into the blast furnace. The air and coal mixture propagates through the iron ore during combustion. The technique had massive benefits to blast furnaces, as it is much more efficient and even allows cheaper coal to be used.

By 2001 the site was becoming run down with a threat of closure. The steel works became Carsid that year, and the coke works was closed. The Coal Injection Plant, along with the blast furnace continued until 2008 when the whole site finally closed due to a decline in steel production following the near-collapse of the automotive industry.