The Grimsby Ice Factory was the largest producer of ice in the world. Compressors from the 1930s are still in place and are the oldest and largest example of such to remain.

History of the Grimsby Ice Factory

The Grimsby Ice Factory was built in 1901 to produce ice for the fishing fleets. At the time refrigeration techniques were in their infancy and it was not possible to build chilling units onto a ship. Instead, ice was produced in large quantities on land and distributed onto ships before they left port. The fish they caught could then be packed in ice for the return journey.

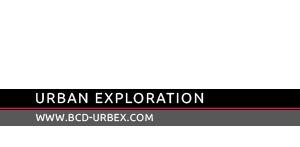

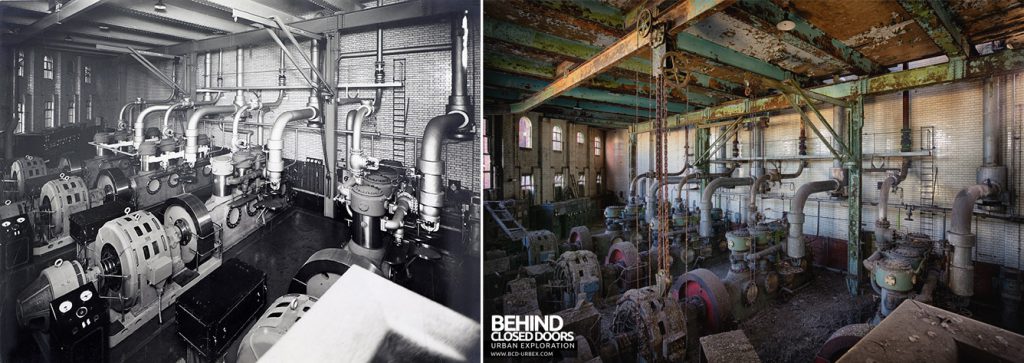

Initially steam was used to power the factory, however as demand increased and the benefits of electricity were realised, the plant was upgraded to use electrically driven compressors in 1930. J&E Hall of Dartford, Kent undertook the task of replacing the refrigeration equipment and Metropolitan-Vickers of Manchester were commissioned to provide the electric motors.

The compressors were the workhorse of the factory. They compress ammonia, causing it to cool down significantly. The heat was expelled from heat exchanger coils on the roof, while the supercooled ammonia was pumped to coils around which brine from ice tanks was circulated. This in turn cooled the brine to around -13 degrees Celsius (8°F).

The tank rooms were where the ice was produced. Freshwater was pumped from two bore-holes beneath the factory and poured into moulds. The moulds were lowered into the brine where the freshwater froze as the moulds were pushed gradually through the tank. Once the moulds reach the far end of the tank the ice was tipped out and crushed ready to be used by the fishing fleet. Conveyors transported the ice directly onto the awaiting ships.

Four of the J&E Hall’s compressors were installed initially, and a fifth unit was added in the 1950s during a further period of expansion. At its height, the Ice House could produce 1,100 tons of ice per day. This made it by far the largest ice factory in the world.

The factory saw expansion to the tank rooms over the years too. In 1907 two additional ice tanks were added, and a seventh during the 1950s expansion. A decline in demand and new technologies for ice production led to the factory being scaled down in 1976. The factory closed down completely in 1990.

Historical Significance

The huge J&E Hall compressors remain in place, and are the only example of such to remain. They are also the largest compressors of this type ever constructed, so they are of great historical significance. The Ice Factory has been Grade II listed to preserve the compressors, however the building continues to fall into a state or dereliction.

The Great Grimsby Ice Factory Trust (GGIFT) was formed to explore ideas for sustainable re-use of the building. A survey commissioned by North East Lincolnshire Council indicates it may cost £5 million to preserve the factory, and many times that amount to fully restore it.

J&E Hall Compressor Details

Ice Tank Rooms

The ice tanks were super-cooled tanks of brine. Buckets of freshwater were lowered into them which froze into ice as they were slowly pushed through the tank.

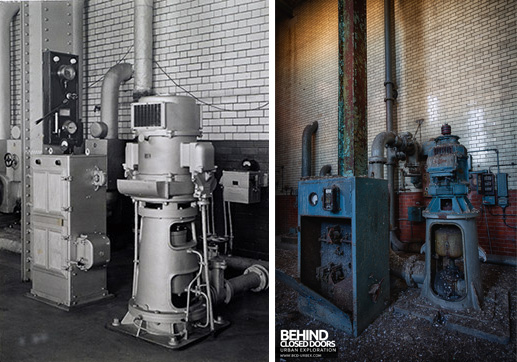

Pumps and Tanks

A number of pumps were used to retrieve freshwater from bore holes under the factory.

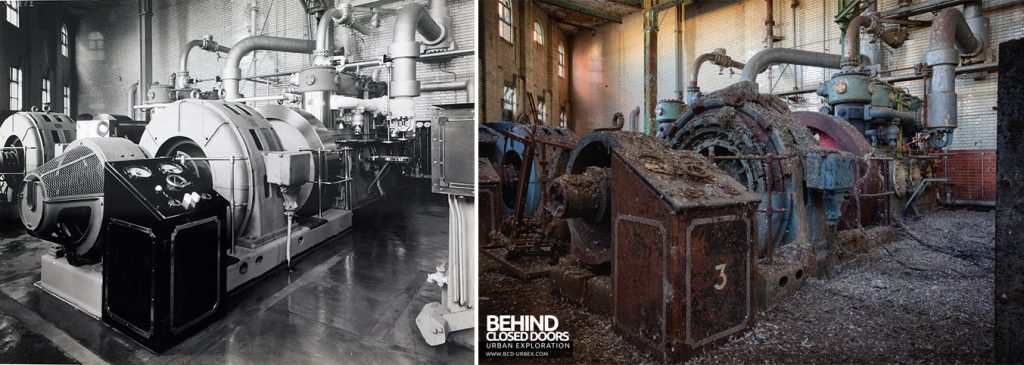

Compressor Number 5

A fifth compressor was added in the 1950s in a seperate, smaller hall.

Other areas of the factory

Industrial excellence!

superb set of shots and report mate.

I love the Then & Now photos!

Amazing set again…

should refurb it get it working again as a tourist attraction,,charge to get in,,sell the ice and it would pay for itself,,,steve rodger.

greetings from indonesia,

would love to see a picture of the evaporator coils inside the tank to compare it to the current type in use around the world

Great photo’s, it is so sad to see it like this. I drive past it every day.

I’m also local, sad to the see the state it’s in now.

Thanks for the photographs. Really appreciate them. So sad that it went in to such a dcline.

Thank you, yes a real bit of history here

Thanks for that, such a shame having worked on the docks for the large part of my working life, and witnessing the slow decline of the docks, very sad. My grandad worked in the ice house for the last few years of his working life.

I would like to just add the Icehouse was started in 1898 and completed in 1908 with the extensions added later, prior to the building of it, ice was transported from Norway on Ice barques.

As a local really appreciated those photos and such a shame as such a iconic and historical place

Brilliant article