Dating back to 1804, Tulis Rissell was a papermakers in Scotland. The mill contained large production lines for making paper.

This was one place I had high-hopes for, with over 200 years of history the mill had plenty of potential for classic old industrial goodness, but progress has done its thing and most of the older buildings have been replaced with new. Don’t get me wrong, it was a big and interesting place with plenty to see, but just lacked the character of many of the other old mills around the UK. The production areas were very modern and almost fully intact, but the older parts that were still standing appear to have been stripped out and cleared many years ago. The oldest areas of the site were demolished in the early 2010s to make way for a biomass power station.

History of Tullis Russell Papermakers

The first paper mill in Fife, Rothes Mill, was established in 1804 on the banks of the River Leven. Robert Tullis founded the company that would later become Tullis Russell in 1809 and built the Auchmuty Mill on land adjacent to Rothes Mill, and by 1836 had acquired Rothes Mill as well.

Work started on a power station in 1912 to provide electricity and process steam for the paper works. This project was completed in 1914 and the building was enlarged in 1921.

The site was steadily expanded over the years, and in 1979 the company opened its fifth paper-making production line.

In 2011 substantial damage worth £1 million was caused to the paper mill in a series of fires which lasted almost 24 hours. At the height of the incident, 40 firefighters were battling the flames. A 31-year-old man was jailed for three and a half years after pleading guilty to wilful fire-raising.

It emerged in 2014 the company had sold 126,000 tonnes of paper, recording a turnover of £124.6 million but suffering a pre-tax loss of £3.4 million. The company had sustained losses totalling £18 million over a five year period and by 2015 had no option but to call in the administrators. 325 employees were made redundant.

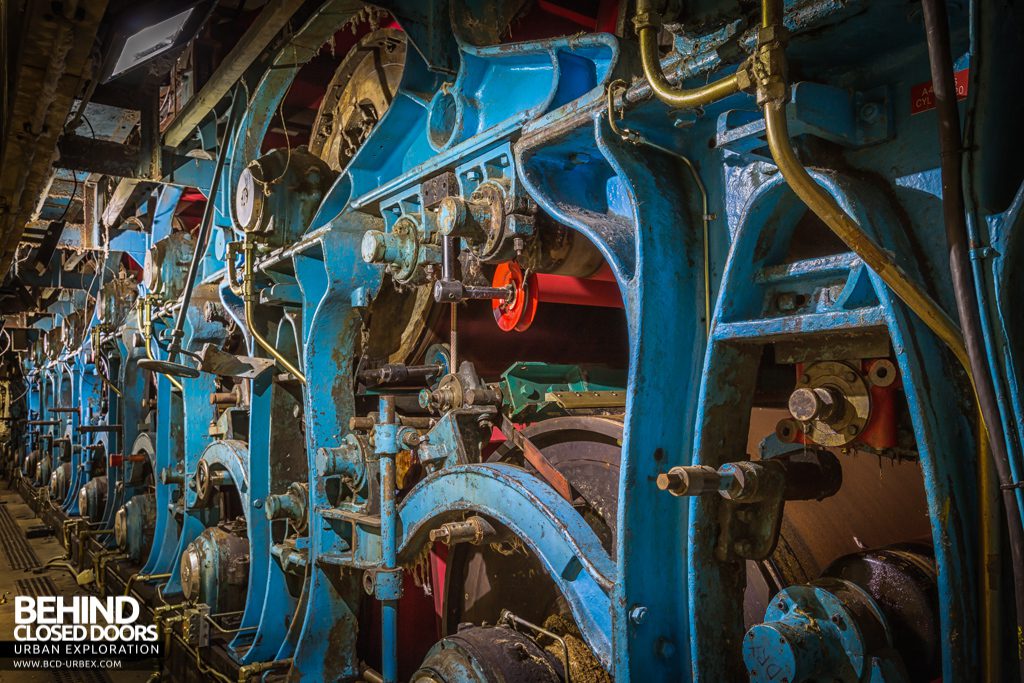

No. 5 Paper Machine

Machine 5 was the newest and largest of the paper making machines at Tulliss Russell

The machine was split between two levels, next we see below the machine

Numerous pieces of ancillary equipment were spread around the building…

Finishing equipment was installed at the far end of the building…

No. 4 Paper Machine

The next building contained the older paper machine no. 4 which was largely dismantled and stripped.

Auchmuty Beater House

An older building than the ones that house the paper machines above, the Auchmuty Beater House is where dry pulp or broke (known as the furnish when added to water in the pulper) stored prior to pulping in water in the ‘broke’ pulper for paper machines A4 and A5. The pulp was fed up the elevators and into the broke pulpers which sat at the top. Water was added and the water and pulp mixed together prior to pumping into holding chests, refiners and cleaners and onto A4 and A5 paper making machines

Electrical Department Switch Room

The lab and offices were a bit boring…

Tullis Russell’s Markinch Power House

Tullis Russell’s Markinch Power House

what a trip down memory lane

You have got the machines mixed up, when you say No5 machine it should be No4

Your right jack the machines are mixed. Sad to.see in that condition.

Very sad photos Jack.

Just found this so sad to see even after all those years I was part of this company for nearly 25 yrs my husband longer my gran and great gran back in the early 20 s went to work from a Leslie in the back of a horse cart